Hello All,

while attempting to prepare an inlay for a pearl dot on the fretboard, I bumped the dremel as I

was trying to turn it off. This of course caused a slight gouge. (I wont make that mistake again)

I was supposed to just have to use a brad point drill bit to create the cavity for the pearl

dot. For some reason, this dot that goes between 4th and 5th fret measures 7mm. I’ve tried many

times in the past to find drill bits sized in millimeters locally to no avail. Much less a brad point.

As for the rest of the dots, no problem. I have the bits for them.

Anyway, I thought I would give it try, and router a circle for the dot. I needed the practice,

since I plan on inlaying the peg head with a custom made inlay.

So, though it’s a very, very small area, I’m sure it will need to be filled.

What do you all like to use when you’re filling an Ebony fretboard around a white pearl dot?

Thanks for listening,

Robert

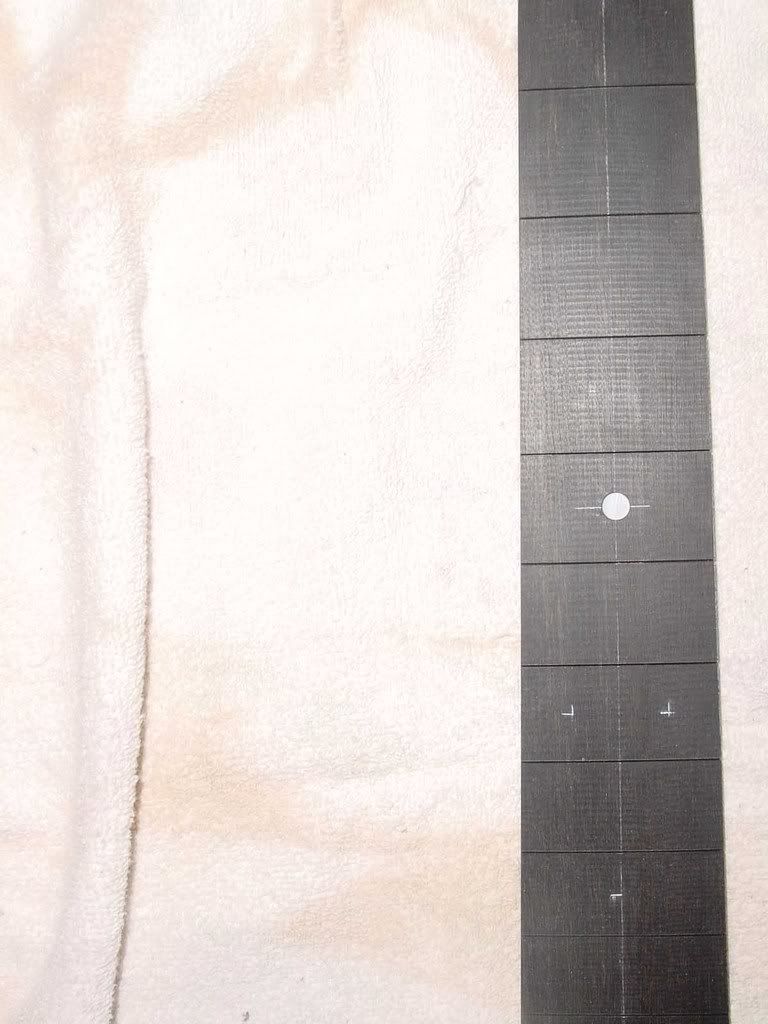

Here's a couple of pics of the fretboard and dot.

What the pics don't show is the router went ever so slightly outside of the desired cut, which I

believe also necessitates the need for filling.

And, as you can see, (or least I think you can see), the gouge is very small.